Discover more thought-leadership on the Management Perspectives Hub.

5G can redefine the way the factories of the future operate. From communications to flexibility to scalability, the potential is yet to be fully realized.

Pierre Teszner, Rockwell Automation’s regional vice-president, Central & Eastern Europe, shares insights from an executive roundtable discussing the importance of digital transformation skills in challenging times for industry.

Åsa Arvidsson, Regional Vice President, North EMEA, at Rockwell Automation, considers the role of people in digital transformation during uncertain times.

Eric Chalengeas, Regional Vice President - South Europe at Rockwell Automation considers digital resilience in the face of market pressures.

How manufacturers can design automation systems that blend software and hardware to deliver a connected and collaborative environment.

Learn the three core principles that underpin Rockwell Automation’s partnership approach and how these serve as win-win outcomes for all members of the PartnerNetwork.

The pandemic experience brought pressures to all manufacturing businesses. For start-ups in particular, survival has been the key priority.

The adoption of cloud is enabling the convergence of OT and IT, helping manufacturers to address challenges on the supply and demand sides of production.

Discover the long-term value of serialization and the ROI of investing in traceability technology.

Discover how traceability technology and connected products can transform your supply chain management and support your digital transformation journey.

How the adoption of software solutions can help manufacturers to position for the next wave of innovation.

Increasing adoption of cloud-based software is helping industrial decision makers to address present business challenges.

How manufacturers can embed sustainability into their culture to drive innovation and improve profitability.

Manufacturing service companies don’t need to go it alone to benefit from innovation. The support of a partner network can lead the way to growth.

Tire producers are beginning a journey that leads to autonomous, self-directed plant operations.

Tire producers are beginning a journey that leads to autonomous, self-directed plant operations.

The State of Smart Manufacturing report revealed common challenges and opportunities from leaders in the industry. Where does your team rank?

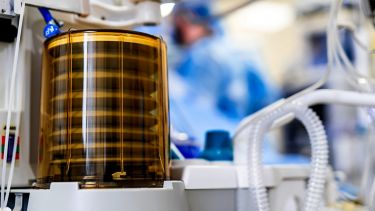

The EV sector is growing at a rapid rate. To fulfil its potential, mass-scale battery production is a necessary pre-requisite.

The ongoing digital skills gap is creating a talent deficiency across the entire smart manufacturing industry. Knowing how to overcome this is key for future growth.

Canninah Dladla, MD for Rockwell Automation in South Africa, shares her insights on ethics as a driving force for the development of good business practice across Africa and beyond.

As cyberattacks on manufacturing businesses continue to rise, the priority for leadership is to address the most common sources.

As we look towards the future of manufacturing, all stakeholders in the sector are united on one issue: the critical importance of decarbonizing.

Talent & technology. Four personnel realities manufacturing organizations must address to be successful in a digital transformation.

This blog from Frost & Sullivan highlights how lifecycle services are evolving to become an essential element of modern operations especially during Digital Transformation.

Forward-thinking organizations are reorienting themselves around a digital-first approach, driven by shifting customer expectations, increased supply chain demand, and a new hybrid workforce.

From conquering downtime to underpinning digital transformation, a tailored support offering can lift a huge weight off your shoulders, while also helping you to become more digital ready.

How capturing and integrating data from OT systems can contribute to product cost, quality, and consistency.

Creating seamless global operations across disparate locations starts with unifying your systems helping enrich the quality of your products and services.

Digitalisation involves holistic change to embed digital capabilities across the organisation. Here’s where to start.

How to support employees with the digital shift.

Modernization isn’t just about upgrading older technology to reduce downtime. It’s a chance to transform your operations to solve your top challenges.

Cybersecurity is a business priority, not just an IT issue. Here are the core elements that can help raise standards across the organisation.

How manufacturing leaders can prioritize resilience, agility and sustainability in order to adapt to an uncertain global environment.

Use your data to its maximum advantage, deploy it where and when it can make a difference, and make the right decisions at the right time.

Discover 3 ways Software as a Service (SaaS) in the cloud for manufacturing can transform your business.

Cybercriminals look for the easiest opportunities. Minimising the risk to your company starts with understanding the threats.

Building a robotic environment based on accuracy, safety and reliability all starts at the design phase.

How remote capabilities can help manufacturers manage pressing concerns and continue to grow long after the impact of the pandemic has passed.

A successful transformation depends on employee empowerment. By blending together people, processes and technology you can create a more engaged workforce.

How technologies like AR and VR work, what sets them apart and what brings them together.

How to avoid derailment on your digital transformation journey. Learn three common challenges that can derail digital transformation in manufacturing.

When done correctly, a digital transformation can have benefits that reach beyond just the operational, as Tetra Pak’s success has shown.

Slowly but surely, the digital transformation of the factory is taking place.

How manufacturers can navigate the pitfalls of piloting potentially game-changing solutions and scaling up to full implementation.

Jan Burian and Lorenzo Veronesi of IDC examine existing trends in smart manufacturing and offer three key takeaways for industry leaders, going forward.

Before you focus on technology, look at your supply chain’s cultural maturity to evolve and ability to deploy that technology for true transformation.

Here are a few emerging trends in the industrial analytics space that can boost your current strategy and keep you ahead of the competition.

Why executives need to focus on using smart and remote-enabling technologies to connect people and bring greater efficiency, cost saving and resiliency to their operations.

Sarah Dana discusses three major hurdles to Digital Transformation implementation and how to tap into a wealth of experience in your trusted partners.

Digital transformation is the foundation for us to manage data complexity and to provide a better employee experience.

Fresh from a recent global CIO conference, Michel Huy shares his insight on an ecosystem approach to DX.

The series of global lockdowns has compelled businesses and their employees to be more creative in how they communicate and collaborate to achieve productive outcomes.

More widely shared data could benefit industry and society, but it has to be managed, controlled and disbursed in a way that its maximum potential can be extracted.

To differentiate from competitors, OEMs must avoid the risk of being trapped in a commodity corner to become integrated, value-adding service providers.

As manufacturers face pressures from several directions to commit to greater sustainability, Mark Bottomley shares his views on some key areas that can provide a solid foundation for a thriving corporate culture.

How becoming more sustainable can deliver far-reaching benefits across your entire business.

Learn how CIOs can meet their top challenges in creating a digital-first culture and proving the business case for digital transformation.

Rockwell Automation EMEA President Susana Gonzalez introduces her three key suggestions on how to put your people first – now and going forward.

Five ways in which industrial leaders can further their sustainability goals by focusing their efforts on improving efficiency.

How Sustainder is lighting the path to smarter cities with a smarter, disruptive manufacturing method.

For many years, the negative externalities of heavy industrial operations were brushed off as merely the cost of doing business, or an inescapable feature of working with damaging by-products and high-temperature environments.

Meaningful change is rarely achieved on the first attempt. Learning from a false start is vital for successful transformation.

Many think that optimising a smart factory means moving away from the use of manufacturing execution systems, but this couldn’t be further from the truth.

The past year has demanded many changes in the way we behave. But can we take what we’ve learned to help us live and work better in the future?

Whether you’re making good progress on your digital journey, or just realising that digital transformation is the key to survival, understanding current and future trends is essential.

Organisations accelerating supply chain innovation through digital transformation can handle market disruptions better; get product to market, faster; and manage a disappearing workforce.

On the DX journey, a skilled CIO can align leaders on strategy, facilitate enterprise-wide cultural change, and use emerging technologies to innovate.

VR will continue to grow in prominence and popularity in manufacturing and industry, thanks to the many benefits it offers.

At the onset of a new paradigm in manufacturing, industrial leaders are placing their focus on key areas that will shape their digital future.

Companies need supply chain processes agile enough to make faster changes, and resilient enough to recover from a lack of raw materials, product or capacity.

Digital Transformation isn’t just an IT issue. Defining the business strategy behind technology adoption will massively increase the odds of success.

As companies prepare industrial operations for the future, they need a strong partner ecosystem that can help accelerate their digital transformation.

Key steps your organisation can take to break through resistance and make positive digital change.

How European manufacturers can look to the future in planning their post-COVID-19 recovery.

How can manufacturing and technology businesses collaborate to transform manufacturing?

How decades of progress in automation technology is setting the path towards a bright and productive future in manufacturing.

Discover how Rockwell Automation can support manufacturers in conjunction with the government’s Industrial Strategy.

Rockwell Automation Sub-Saharan Africa MD, Canninah Dladla discusses the importance of considering human behaviour in your company’s cybersecurity strategy.

How product lifecycle management can help manufacturers to navigate the challenges of Industry 4.0.

For companies wanting to gain business value from smart operations, where should they start? And how fast will they realise ROI?

Technology is one pillar empowering a flexible and resilient company, but the other is strong leadership – particularly, the chief operating officer.

The demand for flexible manufacturing is rising. And the benefits are clear. Find out why getting your people onboard can boost your return on investment.

Explore five areas executives at industrial manufacturers should focus on to put their business on the right digital path.

The future of work is being driven by forces changing how and where we work: specifically, automation and cognitive technologies, which are augmenting how people and machines work together.

Rockwell Automation Sub-Saharan Africa MD, Canninah Dladla discusses the importance of digital transformation for South African businesses.

The lessons manufacturers can learn from recent months to help shape their future.

How decision-makers can embrace digital manufacturing without losing the human touch in a post-COVID-19 world.

How Rockwell Automation and KMT are helping manufacturers operating in Egypt to realise their digital potential.

As businesses adapt to cope with the COVID-19 crisis, and start to build plans for what comes next, IDC identifies the road ahead into the “next normal”.

Taking a long-term perspective on the impact of digital technology and its potential to deliver lasting business value.