The CHIPS Act 2022

Boosting American Manufacturing of Semiconductors

The passage of the CHIPS and Science Act of 2022 paves the way for the strengthening of the semiconductor supply chain in the United States, supports the growth and diversification of our workforce and enhances technology development for years to come. Funding in the form of grants and tax benefits available to semiconductor manufacturers and chipmaking equipment suppliers will enable many companies to produce a reliable domestic supply of semiconductors, critical to American economic and national security.

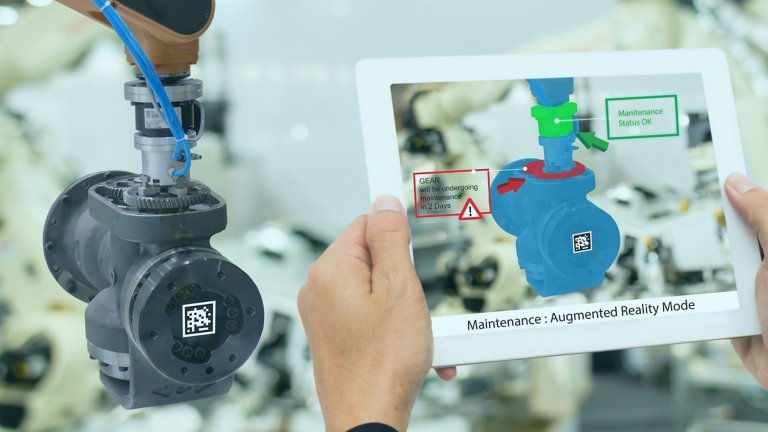

The scale and complexity of these semiconductor fab greenfield and brownfield projects enabled by CHIPS Act funding cannot be underestimated. A key component of any project will be the selection of an industrial automation provider and digital transformation partner that is aligned to the implicit goals of the CHIPS Act.

Rockwell Automation Quick Facts to Consider:

- Rockwell Automation is an American provider of industrial automation and transformative digital technologies, headquartered in Milwaukee, Wisconsin in the United States of America.

- Our technology and expertise have supported the growth and advancement of American manufacturing for 120 years.

- We have served the semiconductor and high-tech industries for over 30 years.

- Our solutions help clients to achieve results in the areas of process tool automation, facility management control systems, material handling and wafer transport, cybersecurity, production optimization and achieving sustainability goals.

- The company has invested in research and development, science and technology and the workforce of the future to help the United States lead in the industries of tomorrow.