QuickStick® is an intelligent conveyor system that increases throughput and reduces total cost of ownership. It provides assembly and process automation markets with a faster, cleaner, and more efficient alternative to pallet conveyor systems.

Faster Than a Traditional Conveyor

Using MagneMotion® linear synchronous motor technology, QuickStick modules are configured end-to-end, creating an electro-magnetic force to propel carriers up to 10 times faster than traditional systems. QuickStick quickly and easily integrates into the Logix control environment using Studio 5000® Application Code Manager with Machine Builder Libraries. More complex move profiles are possible using a SYNC IT controller with an Allen-Bradly PLC and high-speed vehicle position feedback. Features include:

- Motors available in regular and high thrust

- Independent and bidirectional payload propulsion and control

- Fewer moving parts, which means less maintenance

- Lower energy requirements due to highly efficient synchronous motors

- No power/communication cables on vehicles, allowing long travel distances and superior flexibility

- Built-in anti-collision feature helps prevents damage to payloads

- CE Mark and UL Recognized

QuickStick 100

High Throughput for Small to Medium Loads

The QuickStick 100 provides fast, efficient, clean automation for payloads up to 100 kg. Permissions to travel are requested and granted in milliseconds, leading to smooth and continuous movement on an unobstructed path. The QuickStick 100 regulates the velocity and acceleration of the vehicle based on the limits specified by the user defined move profile and system configuration.

Description: Linear motor with embedded drive, controller and position sensing

Acceleration: Up to 1 G depending on mass

Speed: Speeds up to 2.5 m/s

Stator length: 1 m and 0.5 m

Vehicles per meter: Up to 5 depending on magnet array

Minimum vehicle length: 150 mm

Newtons of thrust per meter: Over 430 N of thrust per meter

Magnet Array Sizes: 3...20 cycles [142...958 mm], Single- and wide-array [78 mm and 129 mm]

Physical motor to magnet array gaps: 1...9 mm

Enclosure: Aluminum chassis with stainless steel cover

Sealed motors available for vacuum, submerged, or extreme environments: No

Repeatability: ± 0.50 mm at specified gap and friction, ± 0.10 mm attainable with calibration

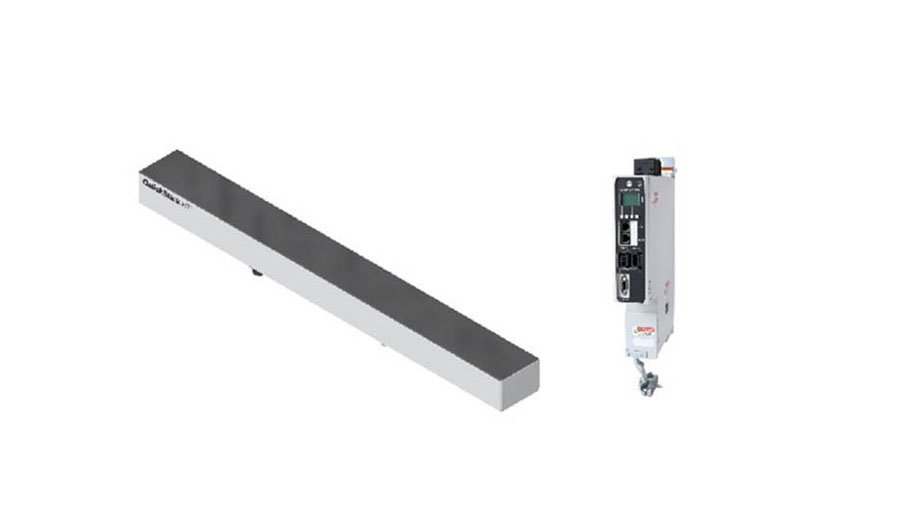

QuickStick HT

Intelligent Automation for Heavy Loads

QuickStick HT is designed to provide fast, precise transport for heavy loads up to thousands of kilograms. It is the ideal solution for automotive assembly or other industrial applications as well as clean room, glove box or submerged applications. The QuickStick HT is easy to use whether you're updating an existing line or developing a new system using the latest technologies.

The QuickStick HT 5700 inverter enables smaller cabinet size and faster speeds. It also provides integrate functional safety for Safe Torque Off.

Description: Linear motor with separate drive and controller and integrated position sensing

Acceleration: Up to 6 G depending on mass

Speed: Speeds up to 5+ m/s

Stator length: Single-wide: 1 m and 0.5 m, double-wide: 0.5 m

Vehicles per meter: 2

Minimum vehicle length: 240 mm

Newtons of thrust per meter: Single-wide: over 2500 N of thrust per meter, double-wide: over 5000 N of thrust per meter

Magnet array sizes: 2...8 cycles [238...958 mm], single- and double-wide [104 mm and 206 mm]

Physical motor to magnet array gaps: 4...22 mm

Enclosure: Stainless steel

Sealed motors available for vacuum, submerged, or extreme environments: Yes

Repeatability: ±1 mm

Safety: Safe Torque Off

Resources

Check out all the software, firmware, documents and training you need to make the most of your independent cart technology investment.

Firmware and Software

Tools

Technical Documents

View the QuickStick Intelligent Conveyor System technical documents

Need a Custom Solution?

We can work with you to implement Independent Cart Technology into a wide range of applications with loads from ounces to hundreds of pounds. Take advantage of a customized solution with all the benefits of LSM, while meeting your needs precisely.