PowerFlex variable frequency drives with TotalFORCE technology offer high-performance motor control, advanced self-monitoring capabilities and real-time operational system data. Customers leverage this smart technology to help:

- Increase productivity

- Boost equipment uptime

- Improve energy and maintenance savings

Whatever your industry or application, low voltage and medium voltage PowerFlex VFDs can help meet your production and operational efficiency goals.

Increase Productivity with Smart Variable Frequency Drives

Turn your manufacturing line into a strategic advantage

Often the workhorses of your operations, PowerFlex VFDs deliver the power you need to drive optimal productivity and provide the real-time information to let your teams make fast decisions to stay up and running.

Unlike other VFDs in the market, PowerFlex variable frequency drives with TotalFORCE technology can:

- Reduce start-up time with automatic drive tuning and adaptive control that automatically adapts to operating conditions and adjusts to maintain production

- Predict internal component life, monitor attached assets and provide advanced notification to reduce unplanned downtime

- Prevent production waste with advanced information to reduce unplanned shutdown events

- Provide a layer of defense against the effects of corrosion with XT corrosive gas protection

Unplanned downtime costs industrial manufacturers nearly $50 billion annually - Forbes

Reduce Equipment Downtime with Predictive Maintenance

PowerFlex VFDs with TotalFORCE technology offer a proactive uptime approach

With the right information about the health of your system, you can reduce downtime, maintenance and spare parts costs and mechanical wear.

Operators are notified of issues that can compromise VFDs or motor health, such as overheating, blown fuses or component runtime hours. With predictive analytics data, you can take action and control your shutdown, repairing or replacing equipment during scheduled downtime.

Increase equipment uptime with real-time data:

- Modeling the equipment’s expected outputs

- Receiving notifications over a secure Ethernet network when drive components reach a preset stage of predicted life

- Receiving motor control performance data in real time – continuously monitoring system health

- Setting analytic models to measure ambient temperature, equipment speed or other characteristics

Reduce Energy Costs with a Smart VFD

Energy consumption is one of the biggest operating costs in manufacturing

Efficient PowerFlex variable frequency drives meet new energy directives for Ecodesign, enabling you to "right size" drives to your application power needs.

- Available active front end technology delivers regenerative energy onto the incoming power supply

- Adaptive control helps achieve optimal drive tuning to maximize output current and motor torque

- Energy pause reduces fan speed and sets PowerFlex 755T drives or Bus Supply into a low energy state

- Harmonic mitigation and power factor correction can reduce energy use

- Reducing motor speed can save up to 50% of its energy use

- Ensure energy efficient operations. Test and validate the PowerFlex VFD and motor combination that is most productive

- Reduce peak energy charges with a synchronous transfer system with PowerFlex 6000T VFDs. It matches power output to the utility’s line power with seamless sync-up and sync-down transition

Increase Productivity, Uptime and Energy Savings

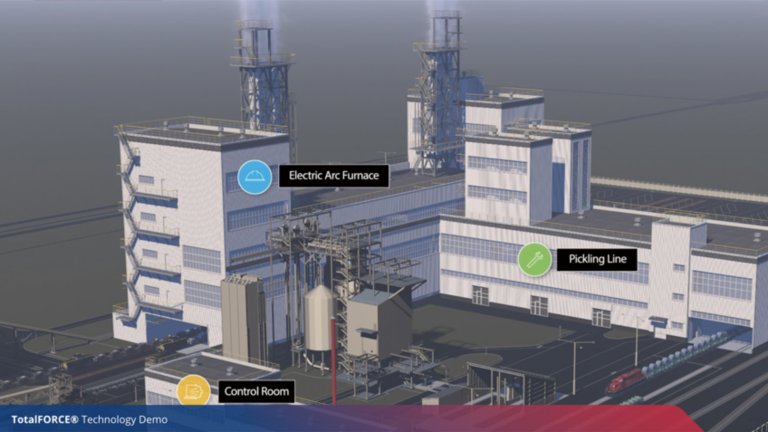

A PowerFlex VFD with TotalFORCE technology delivers real-time industrial control system intelligence

Tire & Rubber

Reduction of unproductive time by at least 10% with efficient PowerFlex drives

Metals

Energy efficiency that amortizes the change in technology in less than 6 months

Mining

The energy savings in multiple applications and operations is greater than 30%

Oil & Gas

Space optimization greater than 50% versus the space of traditional drives