In today’s competitive environment, plant floor asset optimization is mission critical. Creating machines from the ground up that optimize productivity, quality, and safety, while providing insights and information to decision makers when it’s needed is a requirement of best-in-class manufacturers.

Why Smart Machines?

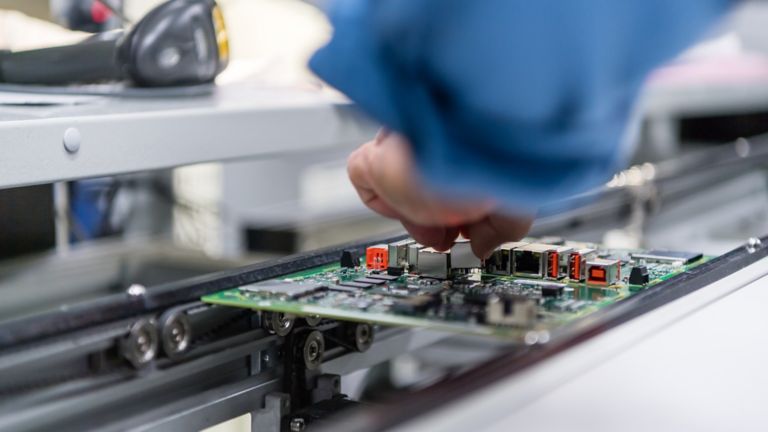

Yesterday’s “smart” machines delivered data. But the smart machines and equipment built today must translate data into insights that drive better decision-making. True smart machines and intelligent equipment use digital technologies to move beyond conventional control, operation and maintenance paradigms. How? Smart devices—smart starts here.

Smart, Safe and Secure

Build smart machines that can bolster productivity – and help manage the safety and security risk inherent to connected operations.

A Powerful Tomorrow Is Within Sight

An increasingly competitive global marketplace, accelerating expectations, regulatory mandates, increasing risks, a shrinking workforce and an unpredictable supply chain. The challenges facing today’s manufacturers are multifaceted and complex. To meet these demands, industry leaders have embraced digital transformation.

Emerging automation technologies will simplify production environments, unleash extraordinary innovation, improve system lifecycle management, and mitigate cybersecurity and safety risk.

Why Modernize?

And why do it now?

It’s all about risk vs reward.

When staying productive is your main priority, why risk wasting time and resources maintaining aging equipment? Start your smart journey with smart devices that give you the information and insights to optimize productivity, quality, risk management, and be more sustainable— get rewarded.

Get smart. Get flexibility. Address manufacturing issues quickly, efficiently and reduce downtime and risks to your workers, assets, and reputation.

Your journey to smart manufacturing starts here.

Digital Twins in Discrete Manufacturing

In this on-demand webinar, you will experience the power of digital twins in the areas of optimization and testing. Our software and tools allow users to create digital models (“twins”) of their production systems to simulate overall performance resulting from specific changes.