The operational stability of iron production and steelmaking processes are under constant threat due to variation in the quality of raw materials as well as other operating conditions. Maintaining consistency and efficient operations while addressing energy savings and emission reduction is key to ensuring productivity.

Challenges by Application

Sinter and Coke

With several operations scattered over large distances, machines coordination is difficult to create and maintain, especially in the event of subsystem failure. A common control platform for all subsystems provides higher yield and quality for sinter plants and proper scheduling and equipment coordination for coke plants.

Blast Furnace – Basic Oxygen Steelmaking

To ensure quality, accuracy and safety, optimized operations are needed to have reliable furnace cooling, automation of cycle times and hot blast delivery, and decreased fuel consumption. Reduce risks and bring process visibility to the enterprise level with a highly available, open and modern distributed control system.

Electric Arc Furnace (EAF)

Rising standards for EAFs require advanced analytics capabilities and a unified control system to gain precise control, power management and energy optimization. Reach this goal by delivering integrated systems and model predictive control technologies.

Drive Efficiency and Reduce Costs

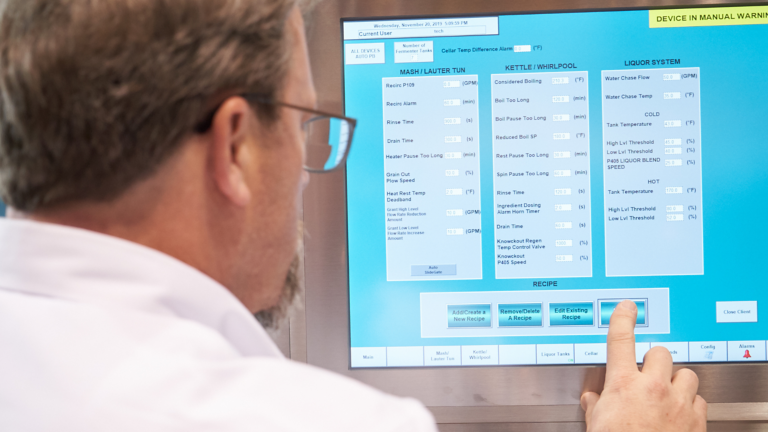

Integrate a Modern Distributed Control System

Address the demanding requirements of iron production and steelmaking processes that system users face, such as the difficulty of balancing high availability systems, connectivity with smart process instruments and seamless interface to Level 3 applications.

A modern DCS can accelerate your digital transformation journey by incorporate the latest developments in process control.

Conquer Energy Challenges and Improve Profitability

Improving energy efficiency in electric arc furnaces can be a challenge. Strategic energy management allows you to gain control of your energy use and reduce consumption with no impact to production or product quality.

Gain real-time energy awareness, identify targeted areas to optimize and improve your efficiency and profitability of operations with energy-specific management systems.

Maximize Performance in Your Steelmaking Processes

Our control, information and safety solutions can reveal new ways to increase production, reduce costs, and increase quality. Find a solution that fits your factory needs.