Designing an innovative and flexible seating system

Upon winning the tender to refurbish the ACC’s seating automation system, HME Services conducted a risk assessment to consider the safety requirements involved with the multifunction use of the venue - so it could be utilised as either an open space venue or tiered seating venue as required.

John Geddes, control systems officer at HME Services, explained that the engineering involved with the project needed to be able to lift the seats above the main auditorium area in a specific sequence and stored while the area was being used as an open space venue.

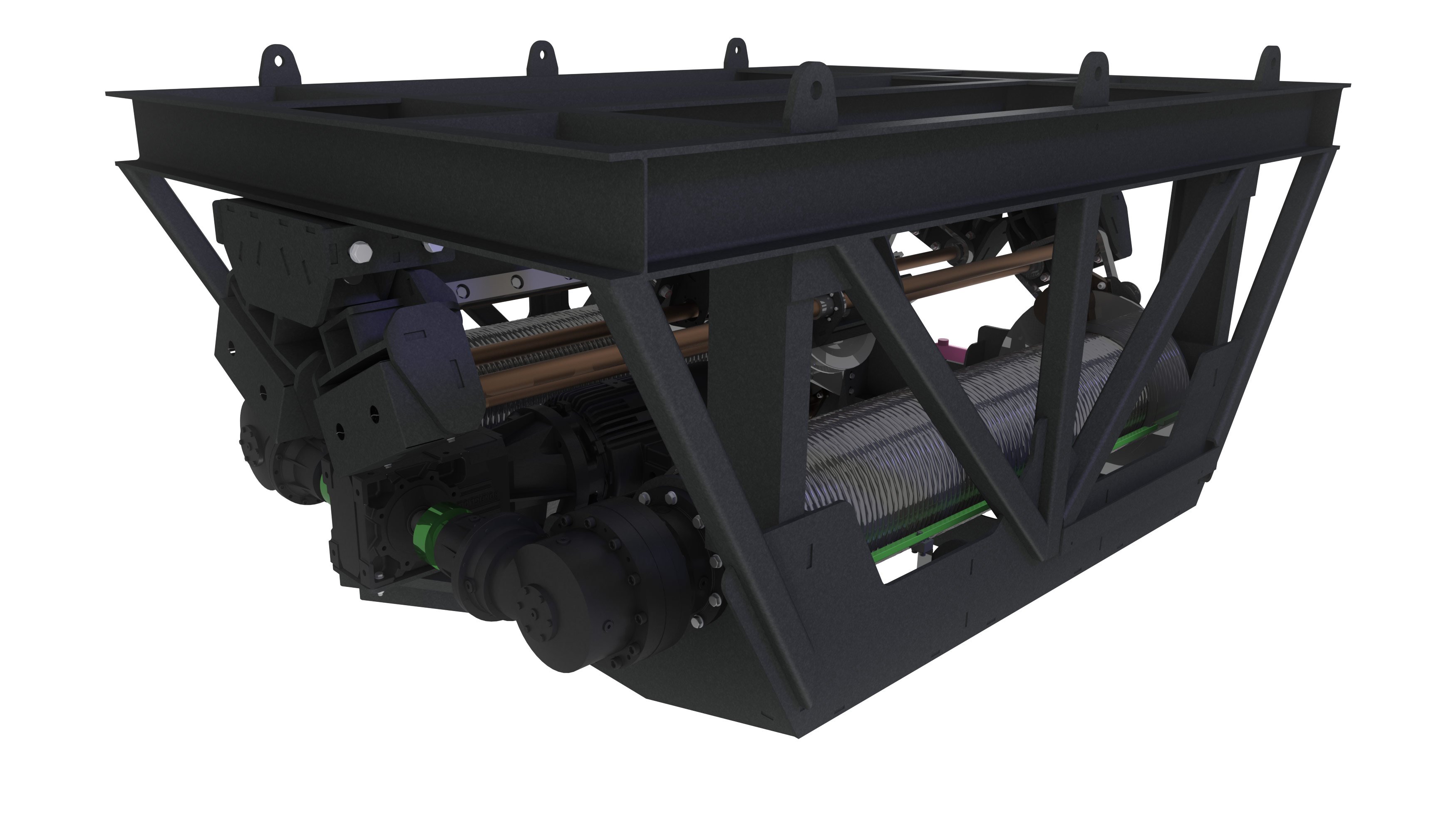

“The seating system design was based on the seats being lifted, housed and locked into the roofing infrastructure when not required. The seating bays are mechanically hinged and are connected to the hoists via quick connect lifting pins. These quick connect lifting pins can be detached from the seating bays and then raised out of site,” said Geddes.

“The risk assessment helped us to identify the hardware that was required to provide a safe environment, which was based on the Allen‑Bradley® Compact GuardLogix® series of PLCs from Rockwell Automation, with integrated safety,” he explained.

The Compact GuardLogix controllers include integrated safety and motion via Ethernet in a single controller. Studio 5000® was used to program the controllers, combining engineering and design elements into one standard framework that enables optimised productivity and reducing engineering time. The same software was used to program safety and motion aspects of the system. PowerFlex® 755 drives were used to power the hoists, with safety over Ethernet.

“The control system comprises a Main Control Cabinet and a Hoist Control Cabinet at each hoist. Utilizing POINT I/O™ modules and Stratix® switches, we were able to integrate control and safety field cabling into a single Ethernet cable run.”