New Allen‑Bradley Compact Box PCs and Thin Clients Provide Cost and Space Savings

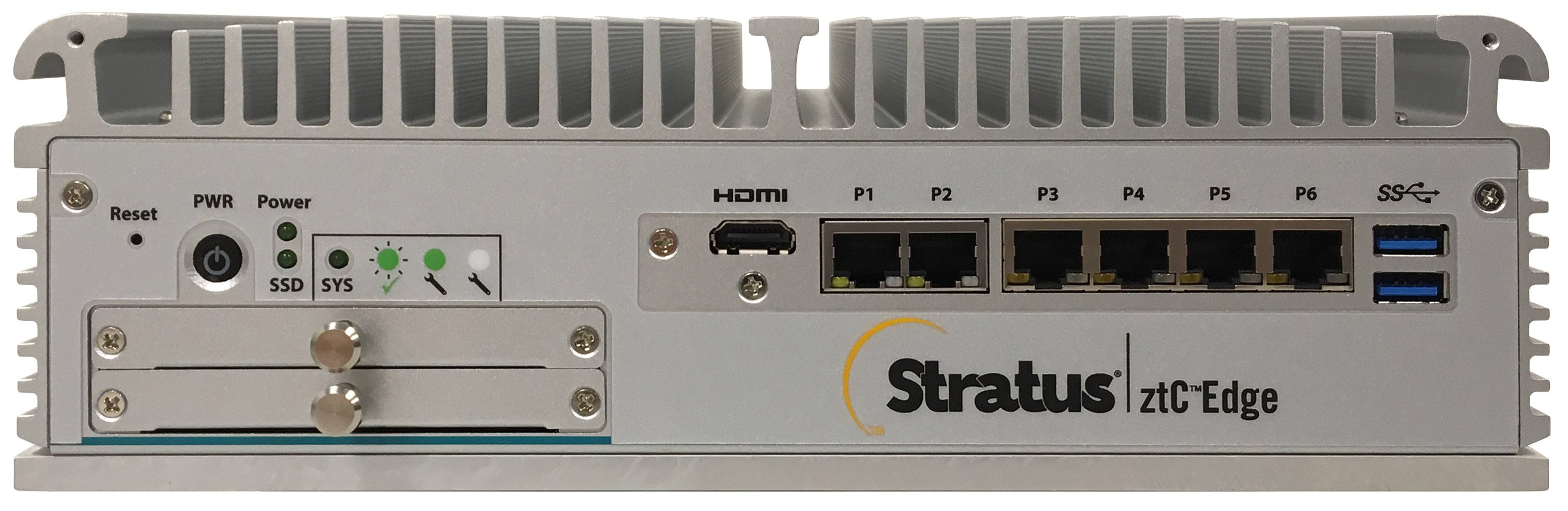

The new VersaView 6300 box PCs and thin clients fit in the palm of a hand, making them the smallest industrial computers to date from Rockwell Automation. The compact design can help users realize valuable panel-space and reduce costs.

The products are also designed to withstand harsh industrial environments. They have a built-in heatsink, can operate in 0° to 50° operating temperatures, and are protected against shock and vibration. They are designed with reduced connection and no moving parts to improve reliability.

“These new box PCs and thin clients are the first of the Allen‑Bradley VersaView 6300 family of industrial computers, and leverage designs and technology from our acquisition of ASEM earlier this year,” said Dan DeYoung, Hardware Business Director,

Rockwell Automation. “The unique designs of the VersaView 6300 family provide a very high level of durability for industrial environments in an affordable, flexible platform.”

Both products work with the Rockwell Automation ThinManager software, which makes centralized and secure application management possible.

The thin clients are ThinManager-ready, and the box PCs are ThinManager-compatible, meaning they can run on a Windows 10 IoT operating system or switch over to run in the ThinManager environment, effectively becoming thin clients. This dual-use option gives users new freedom and flexibility, such as:

- The ability to deliver applications from a central server or a local PC using one product, which can simplify a company’s supply chain.

- The option to load applications from a PC if a central server goes down, which can improve availability.

- The ability to use a PC first as an HMI for a standalone machine, as a thin client for a series of connected machines, or as a data aggregator to collect and share operational data.

Both products use DisplayPort, which supports 4K video for high-resolution content displays. They also have two USB 3.0 ports and two Ethernet ports, making them ideal for high-speed data logging and IIoT gateway applications.