Challenge

- Fluctuating temperatures and weather conditions, and increasing ridership prompted the Dalian Metro to look for ways to better control and reduce energy use

Solutions

- FactoryTalk software suite offers data collection and comprehensive reporting.

- Native integration with the CompactLogix control infrastructure eased system design, commissioning and maintenance

Results

- Energy consumption across the entire metro system is projected to be reduced by 12 percent

- As a result, the metro system predicts 2 percent cost savings per year

Background

China is looking to improve transportation for its 1.36 billion citizens – no small task. Nine of China's largest cities have citywide metro systems. Another 28 cities are building metro lines or planning to build them in the next five years.

Located in the south of the Liaoning Province, the major seaport city of Dalian needed a transportation system to accommodate its growing population. Buses and trams were clogging the streets, and rolling hills throughout the city make bike commuting difficult.

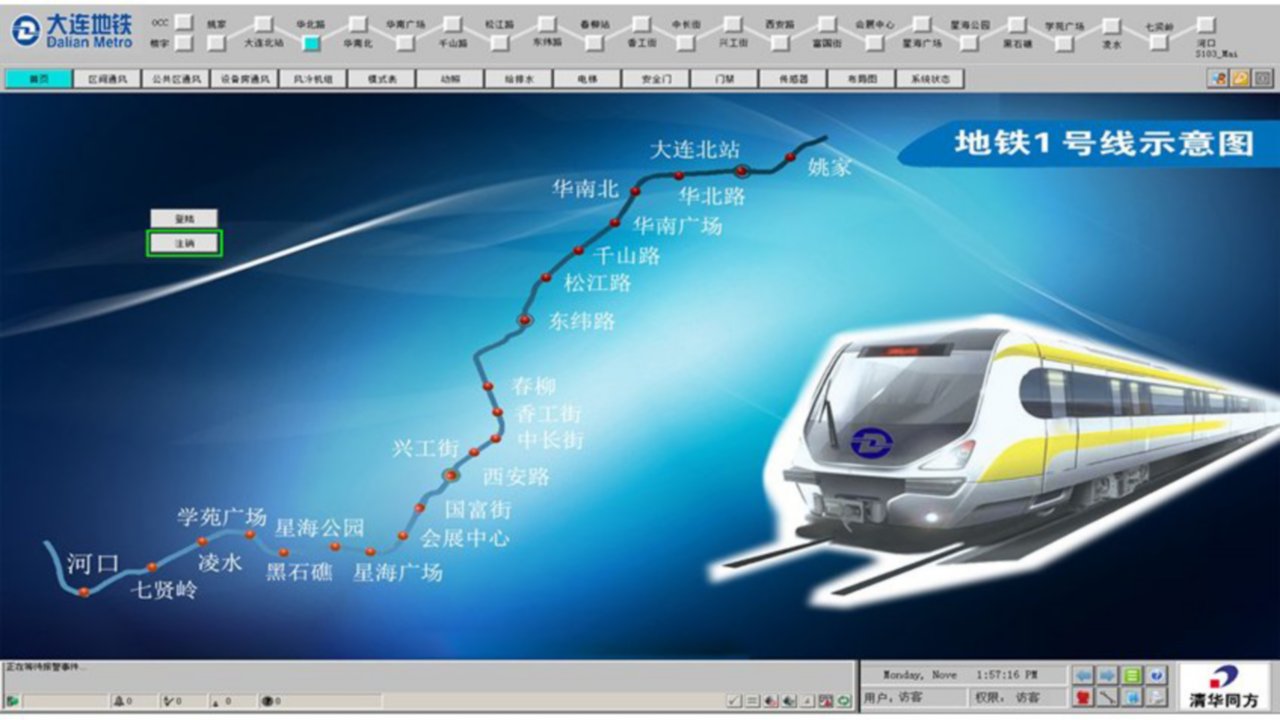

The city's current metro system consists of three lines – two underground lines and one above-ground light-rail line. An additional six new lines or expansion lines are expected by 2020. Spanning over 66 miles, the current system carries more than 100 million passengers annually through 50 stations throughout the metro area.

Challenge

When designing the Dalian Metro building automation control system, engineers standardized on Logix controllers. Operators needed a sophisticated, centralized method of control to effectively manage the HVAC, lighting, emergency signage, elevator systems and other electrical components on the system that stretches across the city.

Additionally, Logix-based systems have proven successful across other major metro systems in China, including Hong Kong, Beijing, Nanjing and Tianjin.

With a new building automation system (BAS), metro system planners aimed to reduce energy costs and keeps commuters comfortable. The city of Dalian has humid, monsoon-filled summers and dry, cold winters, so keeping riders comfortable without overspending on energy for the HVAC system was a challenge. The HVAC system accounts for 55 percent of the total energy usage, and the system's lighting, escalators, safety and other electrical equipment account for the remaining energy costs.

System engineers needed a solution that tied directly into the control system to gain access to accurate data at the individual station level and at the operation control center (OCC).

Solution

The entire Dalian metro system includes more than 50 redundant Allen-Bradley® MicroLogix™ and CompactLogix™ controllers with about 100,000 I/O points across the different stations. A typical station includes two pairs of PLCs as communication controllers to pull and aggregate data from different devices within the HVAC, elevator and alarm systems.

To improve visibility and pull actionable energy data from within the control system, the engineers tapped the FactoryTalk® software suite from Rockwell Automation. FactoryTalk Historian software collects up to 10,000 data tags from PLCs per line. Metrics include station temperature, humidity, carbon dioxide concentration and other environmental data.

FactoryTalk View Site Edition HMI software with a redundant server provides a comprehensive and accurate view into electricity, water and HVAC usage data.

“Controller data is directly integrated with the energy intelligence system to give our operators a holistic view into the BAS operations,” said Hetong Wang, chief engineer for Dalian Metro.

This information is fed to the FactoryTalk VantagePoint® portal from Rockwell Automation, which offers advanced reporting and analytics on BAS data, converting raw numbers into shareable dashboards with actionable information. Trend reports developed with this information allow operators to set the system to respond automatically. For example, as the number of riders increases during evening rush hour at the end of a warm summer day, the system will automatically turn up the air conditioning to ensure riders stay cool and comfortable during their commutes.

Operators can also manually adjust any of the systems from the OCC or a local station if they see a sudden fluctuation in riders or if an unpredicted weather event occurs.

All of the BAS information is monitored, controlled and displayed on Allen-Bradley PanelView Plus™ graphic terminals. Now, the operators at the OCC can monitor electrical equipment and devices down to the station level, allowing them to oversee routine operations and quickly react in case of emergencies.

Results

After implementing the FactoryTalk software suite on top of the system architecture, operators increased visibility into operations across the entire system. With the ability to adjust system performance based on weather, ridership and trends, the Dalian metro system is projecting a 12 percent annual reduction in energy usage, equating to a 2 percent cost savings.

“Not only is the system saving money, but the centrally controlled escalators, emergency exits and signage means the system is ultimately safer for our riders,” said Wang.

Additionally, Dalian commuters are enjoying a more pleasant riding experience, with more responsive climate-controlled stations and trains.

To keep the entire BAS system stable and riders comfortable, Dalian Metro plans to implement FactoryTalk AssetCentre software. The software provides a set of asset-focused tools to centrally and securely manage the BAS across all of the metro stations. The addition will also help with any future disaster-recovery efforts.

The results mentioned above are specific to Dalian Metro's use of Rockwell Automation products and services in conjunction with other products. Specific results may vary for other customers.

Trademark Information:

Allen-Bradley, CompactLogix, FactoryTalk, MicroLogix, PanelView and VantagePoint are trademarks of Rockwell Automation Inc.

Published February 9, 2016