Space-Saving Design

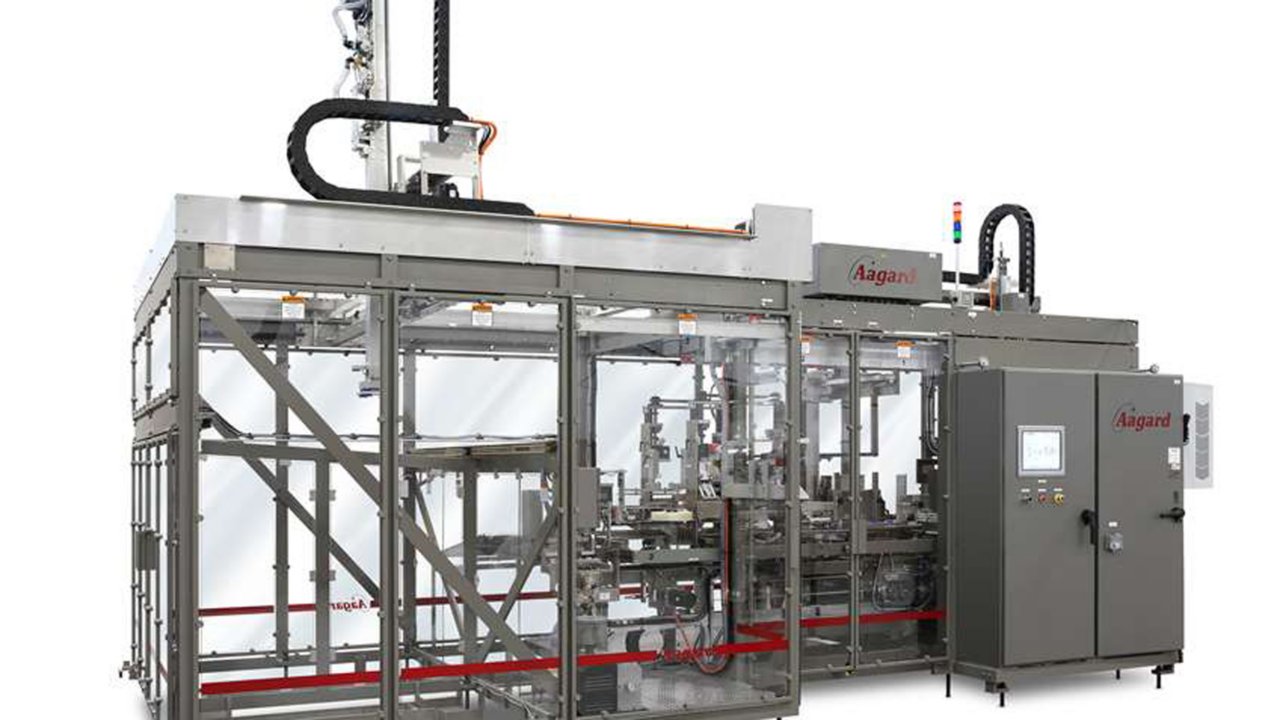

Responding to the industry’s need for a compact, high-speed solution for cartons, Aagard recently added a new offering to its Aspire® line of combination systems. The new Aspire CCP is a combination cartoner, case packer and dual palletizer system.

“Initially, we developed this machine for a confectionery customer who had about 12 packaging lines in their plant, Norlien said. “They needed a flexible system with a high-speed infeed to handle small cartons of candy at the end of each line.”

The product cartons enter the Aspire CCP system directly from the upstream primary packaging equipment via conveyor. Using a high-speed stacking assembly, the system creates appropriate pack patterns for retail-ready cartons. The cartons are erected, filled and sealed – and advance through a quality inspection station on route to the case packer.

The case packer builds the pack pattern and loads the retail-ready cartons in an erected corrugated case. The case is sealed and advances to the final section of the machine. Here, dual servo gantry palletizers build pallets case by case and discharge them.

In a footprint more than 50 percent smaller than conventional lines with multiple machines, the Aagard Aspire CCP packs 30 retail-ready cartons and 10 cases per minute. To achieve this speed, the machine handles 635 product cartons per minute at the infeed.